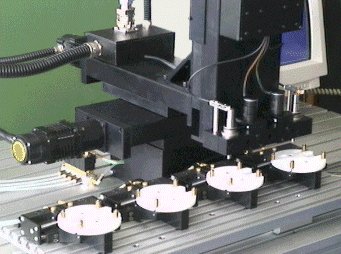

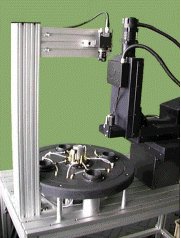

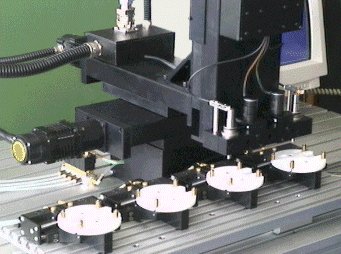

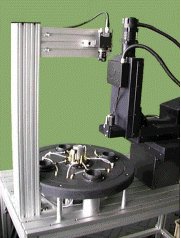

| The precision spindle is an essential component of the engraving system.

It is floating and processed by a brush-free servo motor. Using the floating mechanism, along

with a sensor that registers the positioning of the tool onto the glass, we are saved the trouble

of a time-consuming Z-contour programming for the glass to be engraved. Instead, the tool rests on

the glass with a constant mass and follows the surface contour automatically. The intensity of

engraving is regulated by the spindle frequency relative to the current speed on the engraving pattern.

|

|